Titan Series 6030

Titan Series 6030

or

Call 1-866-609-2672

Description

Jordi's TITAN series has three laser cutting equipment pieces that are quite possibly the largest on the market. On the 18030 model, they range from 6 to 18 meters long. .

The added work area boosts the production process. This allows for greater autonomy without the need for machine operators and double heads for greater production. .

Sliding doors facilitate the access to cabin machines for equipment work supervision and maintenance by the operators. Programming for serial parts and nexting is simple..

Compactness Its design facilitates a multitude of applications. .

Rigidity Construction stability allows for high strength shift..

Durability Built with the best components .

Security Class IV systems.

Maximum cutting thicknesses according to KW and the type of material to be cut.

Machine structure and working size

The gantry axis on the cutting deck (Y-axis) relies on a set of sliders and a high-precision guide for a linear drive. This guarantees high rigidity, minimal resistance to friction, and high load capacity. It is driven by a backlash-adjustable precision rack-pinion reduction rectifier system made from special hardened steel for maximum output and connected to an absolute metered servo motor.

The transverse linear axis (X-axis) features the same system as detailed above. A nozzle support head (Z-axis) equipped with a vertical guide system (spindle).

A constant distance is maintained between the nozzle and the material (only for metals) by means of a capacitive sensor. Before the cut, the non-contact cutting "head" detects the exact position of the sheet metal.

PRECITEC cutting head

This solid state laser cutting head features a high power PRECITEC Procutter with sensor for tracking metal surfaces and a glass-protected 200 mm focal lens holder.

The focal position adjustment is motorized and automatic.

• An anti-collision system is included.

EG 8030 adjustment box, 200 mm focal lens, protection glass, and nozzles for all thicknesses and ceramics are included.

The cutting head contains a 90° 100mm focal collimator.

Air tightness is improved compared to HPSSL and HPSSL + Compact design.

• Protection windows are motorized.

A LED bar shows pressure, temperature, contamination, and TCP.

Bluetooth® application allows for viewing parameters via mobile devices.

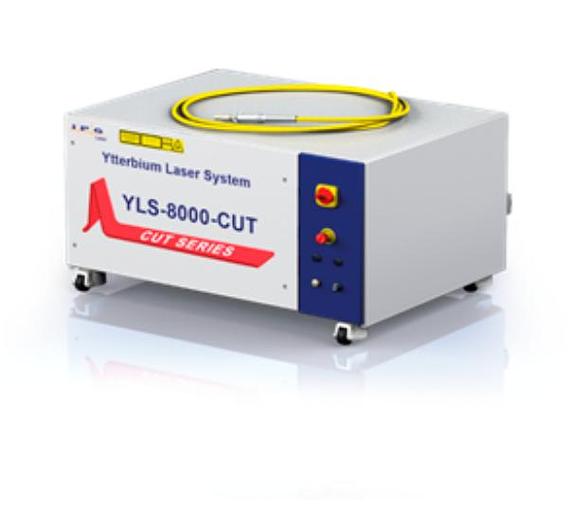

IPG Fiber Laser Resonator

The fiber laser resonator is a separate unit not attached to the cutting machine. This facilitates laser design with high-speed cutting of thin materials and high-quality cutting of thick materials..

The unit contains the highly and kinematically stable resonator. The laser resonator includes a communication system with the control unit and a closed cooling circuit. .

We design the most flexible and reliable machines on the market. Therefore, the TITAN series includes an integrated fiber laser source. This new laser cutting equipment comes with full warranty plus effective commissioning, operation, and monitoring with easy maintenance. It includes numerous special functions that offer the user a wide variety of specialized information on laser applications..

PRECITEC PRO CUTTER 3D Special Cutting Head

The TITAN 3D cutting head is a compact 5-axis fiber laser bevel-cutting unit with collision protection. It was created as an advanced bevel-cutting solution. .

Bevel cuts can be made in simple contours and straight cuts with +/- 45° cuts and a high range of rotation. .

AC servo drives guarantee high power, precision, and low maintenance. .

It has integrated collision protection function.

The PRECITEC head provides quick and easy alignment. .

Its +45° to -45° bevel angle has a fiber laser source. .

Make adjustments from 0° to 45° in less than 2 seconds. .

The 200mm stroke allows for ideal combination of the unit with other cutting processes on a single machine. .

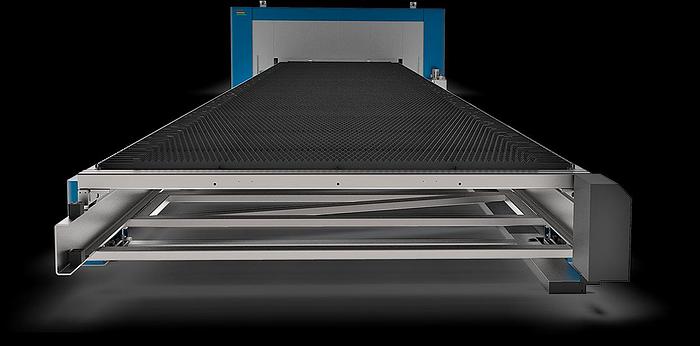

Change Table (Standard)

The sheets are loaded on the cutting table automatically, quickly, and safely. Handling of the laser cutting installation is much easier and more intuitive.

Automation option: Upload and Download

JORDI TECH & INNOVATION has a complete family of automatic loaders with storage towers of up to 50 pallets. These are used to organize the entire stock of materials and enable a more dynamic workflow. .

CAD/CAM Software and Control Panel

Definition of cut geometries

Different fonts

Automatic generation of the cutting sequence

Continuous cutting that minimizes the number of perforations

• Cost calculation

Route optimization

Tables by thickness and materials

Workshop sheets

• Common cut with cut between pieces

Specifications

| Manufacturer | Jordi |

| Condition | New |

| Working Area | 6050x3020 mm |

| Speed X | 170 m/Min |

| Speed Y | 220 m/Min |

| Combined Speed | 280 m/Min |

| Acceleration | 2G |

| Repeatability | 0,02 mm |

| CNC | 675 mm |

| Max Lifiting Load | 4500 Kg |

| Resonator Power | From 2 Kw to 12 Kw |