MPC2000 MC

MPC2000 MC

or

Call 1-866-609-2672

Description

Our Improved Heavy-Duty Construction Cutting Machine

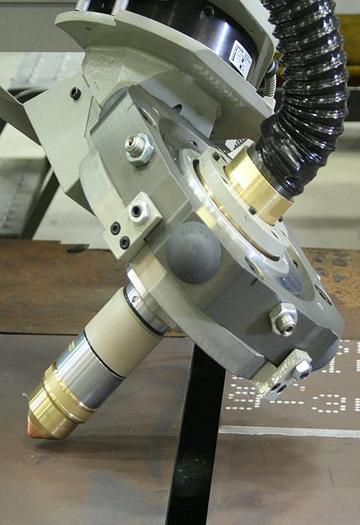

The MPC2000 MC is a highly flexible, multi-process Messer cutting machine that can be equipped with multiple carriages for up to five separate processes including precision plasma, Oxyfuel, drilling up to 2.5”, milling, and markers, with the ability to install up to 4 tool stations.

This plasma cutter delivers clean, smooth cut part edges and precise cut holes, all with high accuracy and repeatability. The MPC2000 MC includes linear motion ways, and state-of-the-art AC servo drives provide dependable machine tool performance.

The drilling and milling high-suction chip vacuum system allows for a cleaner table surface and work area. This system prevents chips from flying off the surface table for operator safety and height-sensing accuracy. There is also a collection hopper for recycling steel chips.

Integrating the MPC2000 MC will improve your plate processing in a number of ways. Built for heavy-duty structural steel processing, in applications like truck manufacturing and tank cutting, this machine is the perfect fit for multiple types of industries such as steel service centers, shipbuilding, the rail industry, oil and gas, construction, mining, and big agriculture.

BENEFITS OF USING THE MPC2000 MC CUTTING MACHINE

Integrating the MPC2000 MC will improve your plate processing in a number of ways.

When you purchase an MPC2000 MC, you’ll gain access to the following features and capabilities:

Materials processed: Mild Steel, Structural Steel, Stainless Steel, and Aluminum.

Material thickness capacity: 26 ga. to 8″ (203.2mm) dependent on process.

Cutting width: 12′ (3.657m) to 28′ (8.534m).

Cutting length: up to 200′ (60.69m).

Drilling up to 2.5″ (63.5mm) diameter.

Tapping up to 1 1/2″ (38.1mm) diameter.

Milling functionality.

Beveling curves functionality.

Contouring speeds up to 400 ipm and positioning speeds up to 1400 ipm.

Enhanced linear motion ways and state-of-the-art AC servo drives.

Long-life band drives.

Larger end trucks.

High suction chip collection vacuum system.

Easy-to-use GlobalControlPlus touch screen interface.

With a dynamic construction your MPC2000 MC may be customized to your needs with the following options, as well:

Plasma up to 800 Amps.

Up to four plasma torches, two markers, and four oxy-fuel torches.

Plasma beveling units Global Rotator Infinity, Delta E, Manual Plasma Stripping Bevel Unit for the X-Axis.

Oxyfuel Bevel Cutters: DAF/L, Single Position Bevel Unit, Three Position Bevel Unit, Oxyfuel Contour Bevel Unit.

Plate markers: Air Scribe, Zinc Powder, Ink-Jet, and Telesis Pinstamp®.

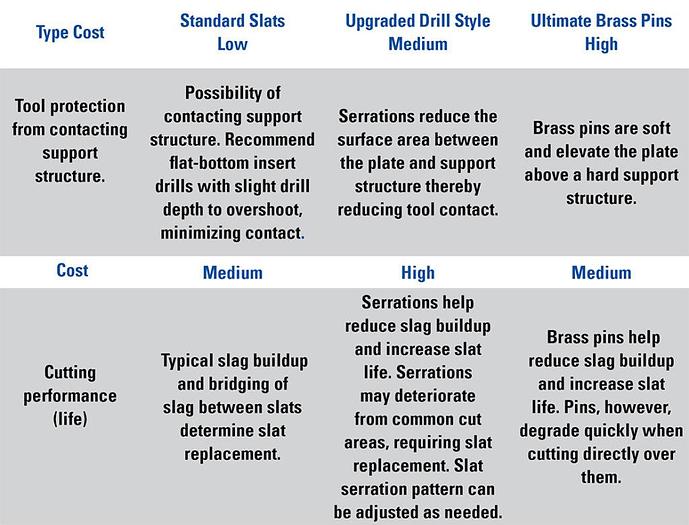

Zoned exhaust tables, such as the self-cleaning Slagger®

Programming and nesting software.

Operators riding platform.

Glare curtains.

See the components section for additional add-ons.

OmniWin is a simple, clear, fast designing and nesting software that can be adapted to the MPC2000 MC for cutting and drilling. It processes cutting tasks for order-based production runs as well as in just-in-time manufacturing, with changing quantities of custom cutting operations. You save time, materials, and it is easy-to-use. OmniWin is the ideal tool for oxyfuel, plasma, drilling, and milling.

Achieve accurate results across applications by programming your machine for your specific purposes, reducing the risk of costly errors.

Consistent performance and repeatable results are critical for maintaining efficient production, and this machine allows you to consistently complete various functions at the same high standard.

The heavy-duty, rugged beam design gives this machine a construction tough enough to keep cutting even through three shifts and offers the strength and stability for maximum accuracy and repeatability.

Designed and manufactured in the USA to meet machine tool and ISO 230-2 standards, both UL/cUL.

The MPC2000 MC is equipped with Global ControlPlus for an easy-to-use operator interface. As with other Messer machines, you will gain access to our Virtual Service and Visual Service remote consultation and diagnostics, as well as our Sentry Service preventative maintenance program to keep your machine in working condition.

You will also benefit from installation flexibility with right, left, or overhead powertrack options. Also an optional operator riding platform and operator glare curtain for enhanced safety and efficiency.

Specifications

| Manufacturer | Messer |

| Condition | New |