MPC2000

MPC2000

or

Call 1-866-609-2672

Description

Your Highly-Flexible Drilling and Milling Machine

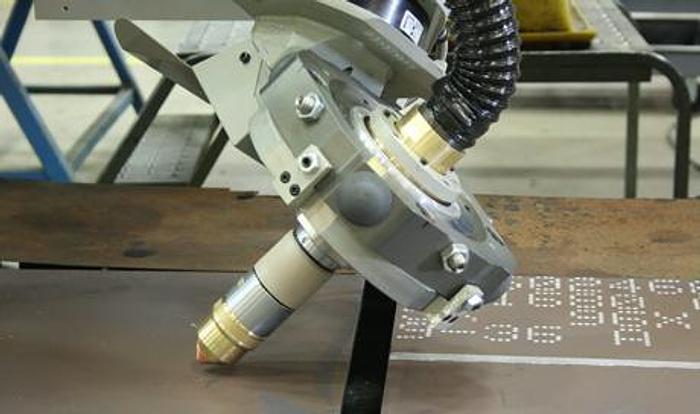

The MPC2000 is a multi-process Messer cutting machine and heavy-duty workhorse. This machine can be equipped with multiple carriages, as well as up to five separate processes including precision plasma beveling, oxyfuel beveling, 2″ drilling, and markers.

The MPC2000 features enhanced linear motion ways, and state-of-the-art AC servo drives provide dependable machine tool performance.

The rugged dual beam construction makes it tough enough to keep cutting, even through high production, working three work shifts with 24/7 operation. Long-life band drives and larger end-trucks offer strength and stability for improved accuracy, repeatability, and durability across a range of processes for workshop efficiency.

Built for Heavy Duty Construction, Structural Steel, Shipbuilding and Steel Service Centers

The MPC2000 is suited for ship builders and steel service centers alike. From Big Agra to the rail industry and a number of material handling environments, the MPC2000 can provide immense benefits with its durable construction, flexibility, and reliable performance across processes.

Suited for Transportation Industries

This versatile and flexible machine is suitable for a wide range of applications, from truck manufacturing to tank cutting. The MPC2000 performs well in a variety of industries and environments due to its highly-flexible design.

Standard MPC2000 Machine Features

The MPC2000 is a multi-process cutting machine designed for dependable, durable performance.

Performance capabilities include:

Cutting width: 8′ (2.438m) to 28′ (8.534m).

Cutting length: up to 200′ (60.69m).

Contouring speeds: up to 400 ipm.

Positioning speeds: up to 1400 ipm.

Material Thickness Capacity: 26 ga. to 8″ (203.2mm) dependent on process.

Materials Processed: Mild Steel, Stainless Steel, and Aluminum.

The dynamic construction of the MPC2000 also includes the following standard features:

Can be equipped with multiple carriages and up to five separate processes.

Includes linear motion ways and state-of-the-art AC servo drives.

Capacity to install a total of four separate tool stations, including plasma torches, oxyfuel torches, and markers.

SureStop Collision Sensor.

Remote consultation and diagnostics with Messer’s Virtual and Visual Service™.

Global Plus Software

GlobalControlPlus comes standard on the MPC2000 with easy-to-use learn, touchscreen interface which is easy to comprehend, and operate. Equipped with the latest software technology, OmniWin, OmniBevel or OmniFab (tailor-made, customized workflow for maximum production).

MPC2000

Specifications

| Manufacturer | Messer |

| Condition | New |