V-21/26APC

V-21/26APC

or

Call 1-866-609-2672

Description

Automatic vertical band saw with the ability to miter from 60° left to 60° right.

A heavy duty vertical saw, the V-21/26APC efficiently cuts both solid and structural material and is extremely versatile for many different types of sawing applications. This model features user friendly, graphical icon programming for miter cutting.

Featuring a large 26″H x 21″W capacity, 10 HP motor, and 1 1/2″ blade, the V-21/26APC is a reliable choice for all your automated vertical metal cutting applications.

STANDARD FEATURES

4 ° canted head allows for efficient cutting and improved blade life

60″ bar feed, left side

Shuttle features automatic multi-indexing up to 60″ (120″ optional) in a single stroke with automatic kerf compensation. Powered by a rack and pinion servo drive.

Automatic programmable mitering with “go to” angle functionality from 60° left to 60° right

Hydraulic head tilt

Cast iron band wheels

Hydraulic DDF system

Two full stroking hydraulic vises

Hydraulically powered, programmable guide arm attached to saw column.

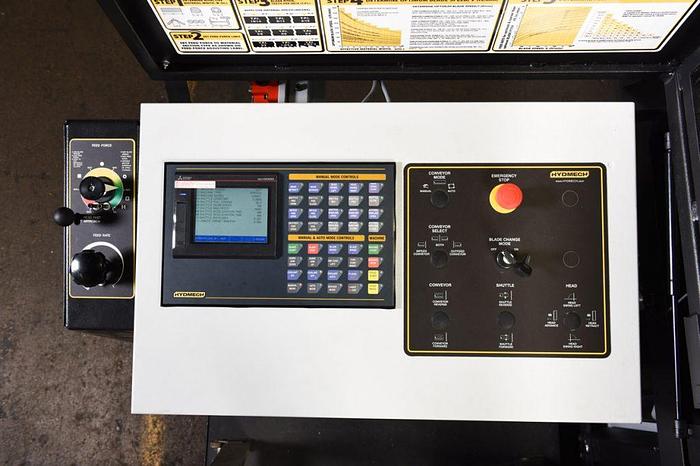

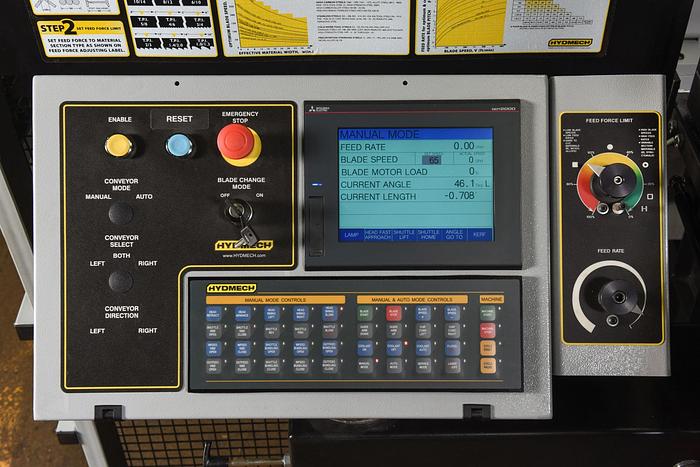

8.5″ Mitsubishi FX5U PLC color touch screen controller. No flipping from screen-to-screen, the control is interactive with messages for the operator that reduces the learning curve. User Friendly Graphical Icon programing for miter cutting, 1000 jobs, 20 jobs in queue

10 HP VFD. True direct blade drive – no belts/pulleys

Blade chamber separates material from cut part

Hydraulic chip conveyor

Replaceable blade brush

Robust steel base

Out of stock switch

Blade breakage switch Easy access electrical panel and hydraulics

Pop-up feed roller – one, opposite bar feed

Hydraulic band tensioning with digital readout

Replaceable carbide guide inserts

3 HP hydraulic pump provides system pressure

Safety door interlocks

Flood coolant with wash down hose

Laser light

Work light

Variable vise pressure

Automatic, Hydraulic Powered Mitering

Mitering from 60 degrees left to 60 degrees right. The control panel features a digital angle display. Head tilt is controlled hydraulically.

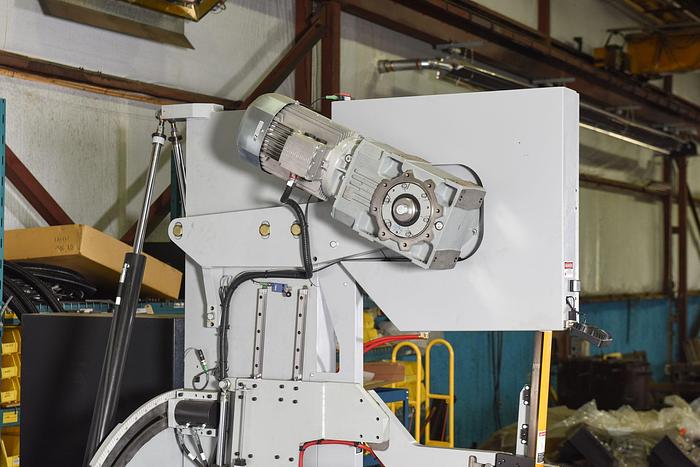

10 HP Blade Drive

The Motor and Gear box are bolted together. This results in better transfer of power between the two moving parts. Other benefits include lower maintenance costs, better torque, and less vibration resulting in better blade life.

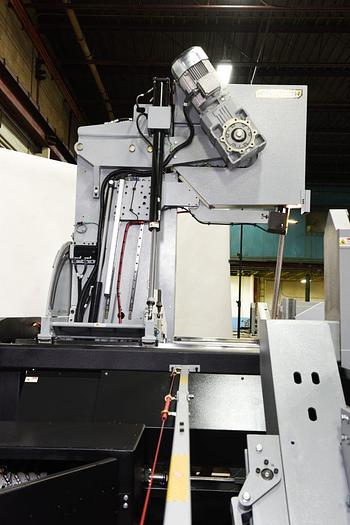

Automatic Multi-indexing

Indexes material quickly and accurately, up to 60” or 120” optional in a single stroke. Shuttle carriage moves on linear bearings and is driven by a rack and pinion servo motor.

S-20 Horizontal Pivot Band Saw Angle Measurement

Graphical Icon Programming

User friendly, graphic icon programming makes programming angles simple for the operator.

OPTIONAL FEATURES

Chip bucket with pump

Full capacity hydraulic overhead bundling

Mist lubrication

Tall square vise inserts

Out feed vise

Out feed vise bundling

Right side infeed shuttle

10’ shuttle infeed

Bridge/interface bracket

Powered bridge/interface bracket

Idler conveyors

Powered conveyors

Power transformer

Specifications

| Manufacturer | Hydmech |

| Condition | New |

| Dimensions | 181” x 184” x 112” |

| Machine Weight | 14,700 lbs. |

| Blade Speed | 65-385 SFM |

| Blade Drive | 10 HP VFD |

| Blade Size | 1 1/2” x 19’ 4” |

| Capacity | 90°, 45° Right, 45° Left, 60° Right, 60° Left |

| Rectangular (HxW) | 26” x 21” (22” x 21” w/bund), 18” x 21” (15.5” x 21” w/bund), 18” x 21” (15.5” x 16.5” w/bund), 12 1/2” x 21” (7” x 21” w/bund), 11” x 21” (7” x 16.5” w/bund) |

| Round | 21″, 17", 17", 12", 11" |

| Machine Voltage | 480 v (all other voltages require optional transformer) |

| Table Height | 44” |

| Automatic Multi-Indexing | 60″ (120″ optional) |