H-22A

H-22A

or

Call 1-866-609-2672

Description

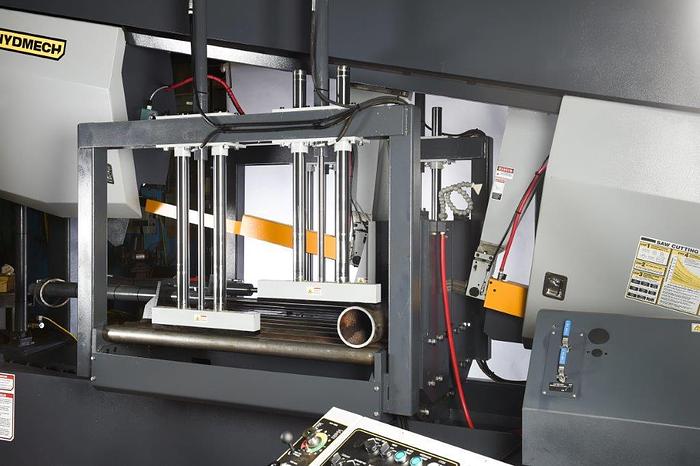

The H-22A is an automatic horizontal band saw providing accurate 90° metal cutting for heavy-duty applications.

The H-22A is fast, with its high speed shuttle feed indexing up to 34″ in a single movement. Its optional 6° degree canted head, recommended when cutting larger beams, structural steel, and bundles of square tubing allows for more efficient cutting and improved blade life.

Featuring a 22″ x 22″ capacity, 10 HP motor, and 2″ blade, the H-22A is a reliable choice for all your heavy-duty horizontal metal cutting applications.

STANDARD FEATURES

One piece design – no alignment necessary

Spilt front vise allows for short remnant length

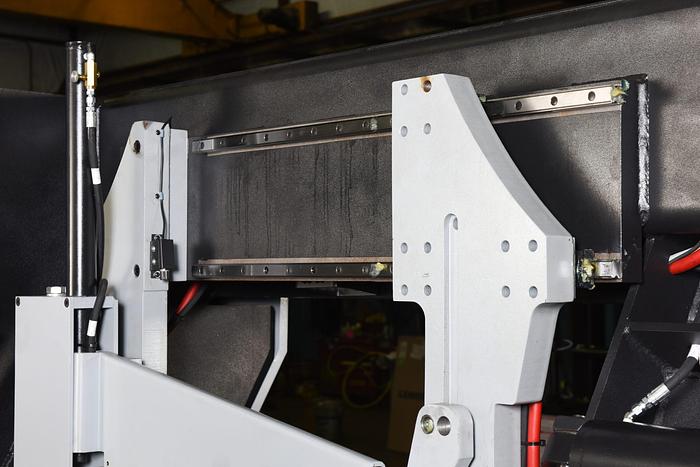

Shuttle features automatic multi-indexing up to 34” in a single stroke with automatic kerf compensation.

Steel guide arms. The idler side guide arm is mechanically connected to the front vise moveable jaw for proper guide arm spacing at all times.

Hydraulic positive down feed

Blade chamber separates material from cut part

10 HP VFD. True direct blade drive – no belts/pulleys Full capacity, full stroking hydraulic vises

High resolution feed rate valve allows for constant feed rate when cutting special alloys

Cast iron band wheels

Automatic PLC control programmable up to 99 jobs with 5 in queue.

Replaceable blade brush

Robust steel base

Automatic chip removal auger

Out of stock switch

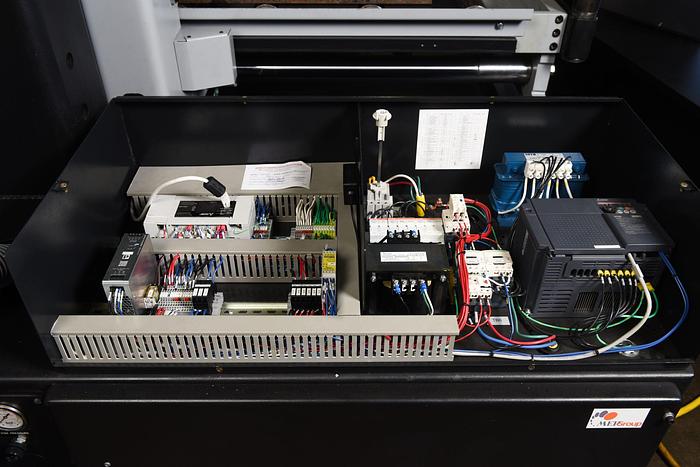

Easy access electrical panel and hydraulics

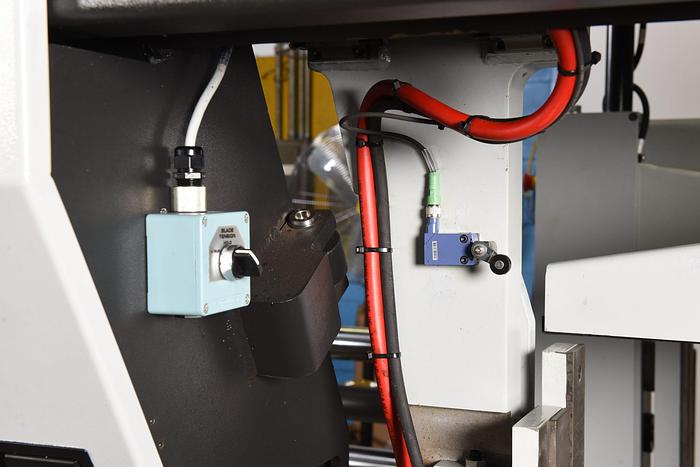

Blade breakage switch

Hydraulic band tensioning with digital readout

Hydraulic carbide guide tensioning

Hardened, replaceable wear plates

Safety door interlocks

Flood coolant with wash down hose

Work light

Variable vise pressure

OPTIONAL FEATURES

Full capacity hydraulic overhead bundling

6 degree canted head

Blade deviation

Mist lubrication

Outboard vise

Outboard vise/w bund.

Pedestal control

Roller discharge table

Vertical alignment rollers

Laser light

Idler & powered conveyors

Powered conveyors

Power transformer

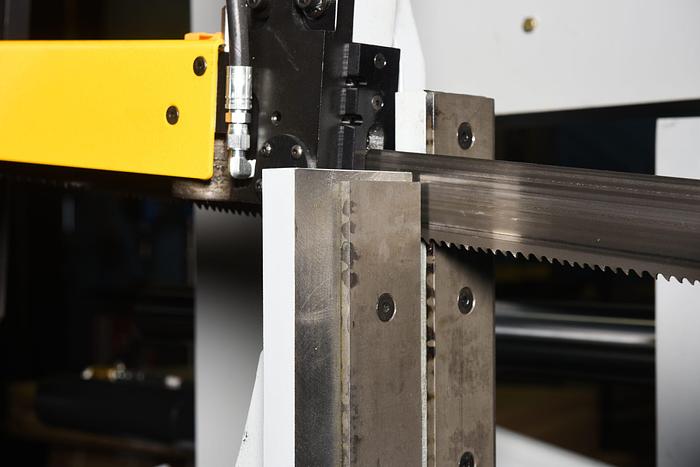

Split Front Vise

The split front vise reduces burrs and allows for holding thin pieces close to the blade on both sides. The blade passes through the vise and the vise holds the workpiece on both sides at the same time.

Two Hand Control

Designed for safety, the two button control on the head and the vises, insures that the operators hands are not in the cutting and vising area during saw operation.

H-22A Full Capacity Vises

Full Capacity, Full Stroking Vises

Allow you to operate the vises faster and hold large pieces better. Full height vises allow you to hold large objects more efficiently, like I beams. Full stroking vises mean you don’t have to manually change the position of the vise operator.

S-20 Horizontal Pivot Band Saw Angle Measurement

Chip Conveyor

The chip conveyor makes cleaning the machine easier. It removes the chips from the machine while it is running, which is safe for the operator and clean.

Specifications

| Manufacturer | Hydmech |

| Condition | New |

| Dimensions | 141” x 88” x 92” |

| Machine Weight | 12,500 lbs. |

| Blade Drive | 10 HP VFD |

| Blade Size | 2” x 22’ 6” |

| Capacity | 90° |

| Rectangular (HxW) | 22″ x 22″, Canted: 20″ x 22″ |

| Round | 22″, Canted: 20″ |

| Machine Voltage | 480 v (all other voltages require optional transformer) |

| Table Height | 31” Canted:35″ |

| Automatic Multi-Indexing | 0-34″ |