H-14A

H-14A

or

Call 1-866-609-2672

Description

Designed for high production cutting with a carbide tipped blade, the H-14A is unlike anything on the market.

With an enclosed design for superior safety, this machine uses 66% less energy than competing models due to on-demand hydraulics which only operates when needed. Its 25 mm remnant length option reduce material waste saving you money!

Featuring a powerful 8.8 HP variable frequency drive motor, the H-14A has a heavy-duty shuttle vise powered by a ball screw and vector motor. This provides material indexing up to 24” in a single stroke with multi-indexing capability.

STANDARD FEATURES

Heavy-duty cast iron saw head

Spilt front vise allows for short 4.7” remnant length

Cast iron shuttle features automatic multi-indexing up to 19” in a single stroke with automatic kerf compensation. Powered by ball screw and stepper motor

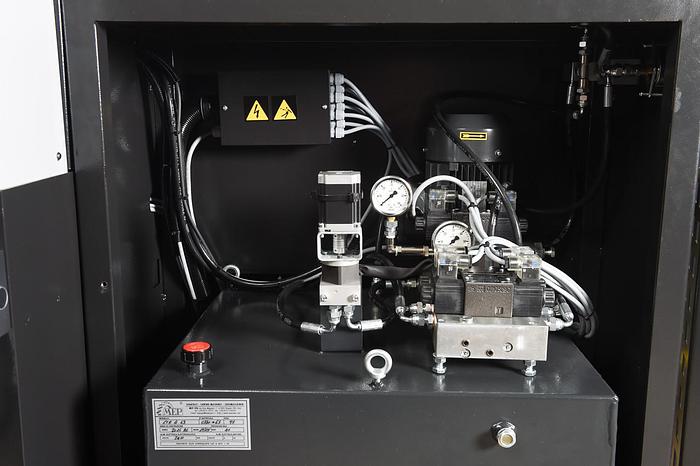

On-demand hydraulics save energy

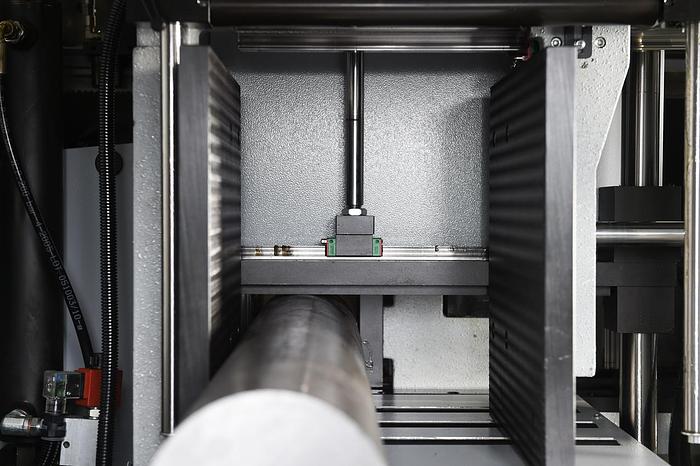

Steel guide arms mounted on linear rails. Hydraulically powered idler side guide arm is adjustable for proper spacing

8.8 HP VFD. True direct blade drive – no belts/pulleys

Full capacity, full stroking hydraulic vises

Hydraulic positive down feed

Blade chamber separates material from cut part

Cast iron band wheels

Automatic PLC, touch screen control programmable up to 100 jobs with 20 in queue

Replaceable blade brush

Robust steel base

Automatic chip removal conveyor

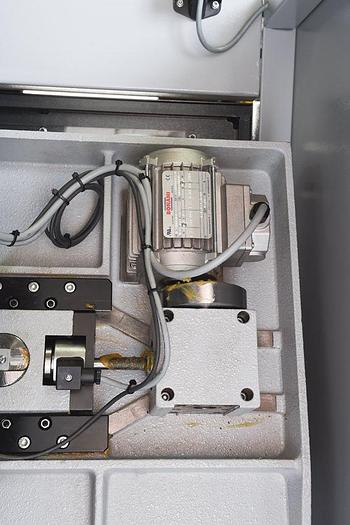

Easy access electrical panel and hydraulics

Blade breakage switch

Blade deviation monitor

Variable vise pressure

Out of stock switch

Designed for safety with saw-in-the-box style

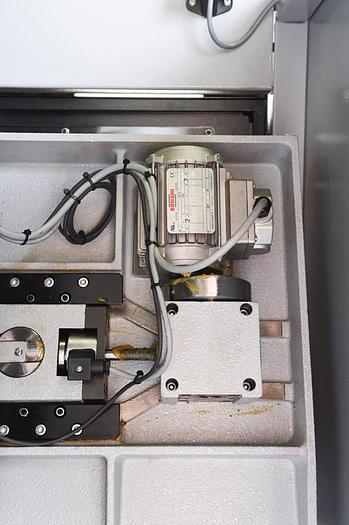

Electronic band tensioning with digital readout

Replaceable carbide guide inserts

Safety door interlocks

Flood coolant with wash down hose

Laser light

Work light

OPTIONAL FEATURES

Full capacity hydraulic OH bundling

Mist lubrication

Vertical rollers

High blade speed

Short remnant of 0.98”

Power transformers

Idler conveyors and accessories

Power conveyors and accessories

Power transformers

Band Tension Monitoring

Electronic Band tensioning with band tension monitoring during cutting. The blade tension is monitored during the cutting process. It will automatically adjust to maintain blade tension.

H-14A Touch Screen Control

Windows Touch Screen Control

Very intuitive and easy to program. Most programming is done on a single page. Most machine operation function keys are outside of the touch screen area so the operator only has to use the touch screen while programming a job.

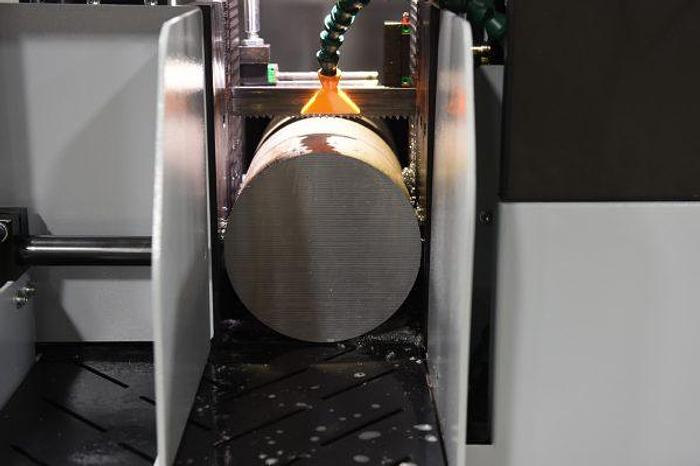

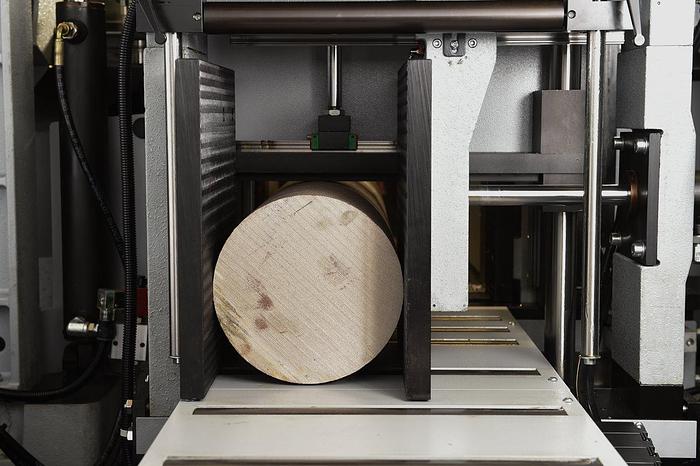

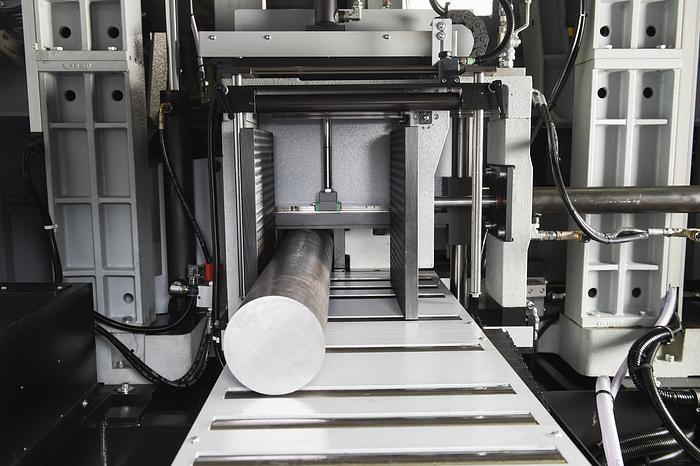

H-14A Blade Chamber

Unique Blade Chamber Feature

Blade chamber automatically separates the cut pieces to allow for clearance. The blade does not rub cut material while raising which is an essential feature for running carbide blades.

S-20 Horizontal Pivot Band Saw Angle Measurement

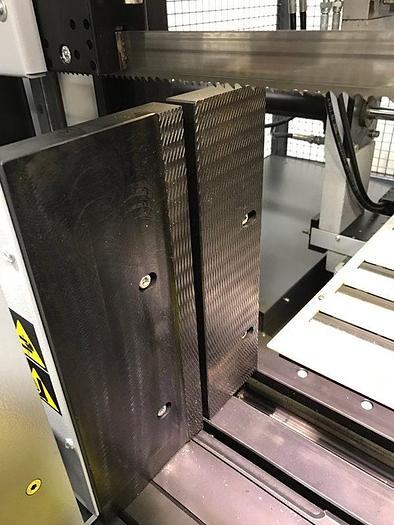

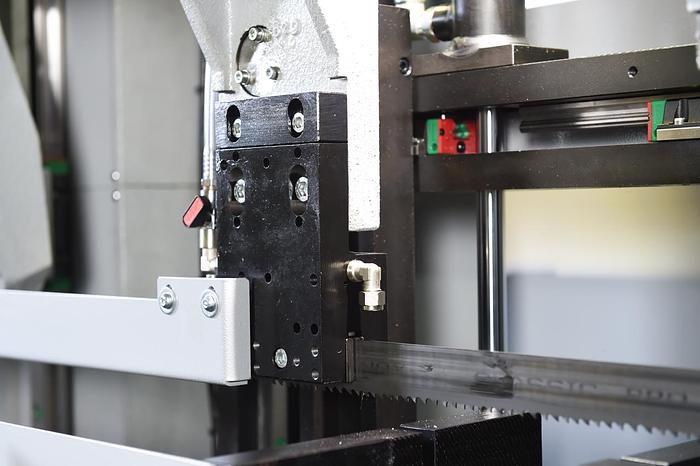

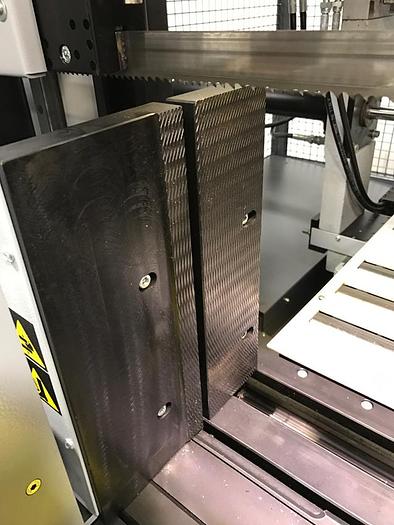

Split Front Vise

Split front vise design will allow for shorter 4.7” remnant for less wasted material in automatic. A shorter rem option is available to get the rem down to 1”.

Specifications

| Manufacturer | Hydmech |

| Condition | New |

| Dimensions | 88” x 63” x 78” |

| Machine Weight | 6,172 lbs. |

| Blade Drive | 8.8 HP VFD |

| Blade Size | 1 1/4” x 15’ 2” |

| Capacity | 90° |

| Rectangular (HxW) | 14" x 14" |

| Round | 14" |

| Machine Voltage | 480 v (all other voltages require optional transformer) |

| Table Height | 34” |

| Automatic Multi-Indexing | 0-24″ |

| Remnant Length | 4.7″, 11″ w OH bundling |