H-360A

H-360A

or

Call 1-866-609-2672

Description

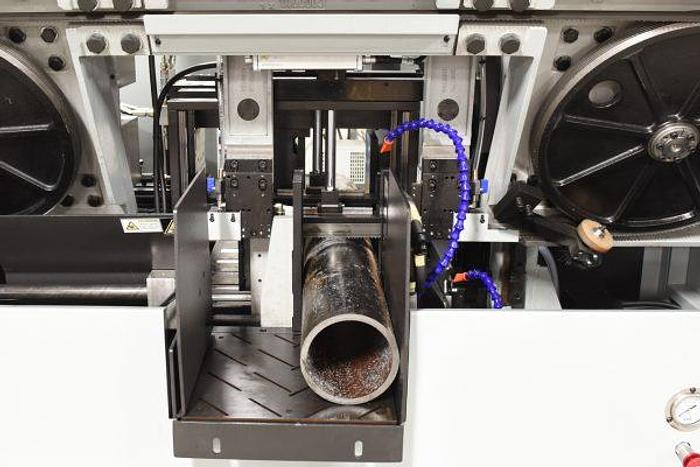

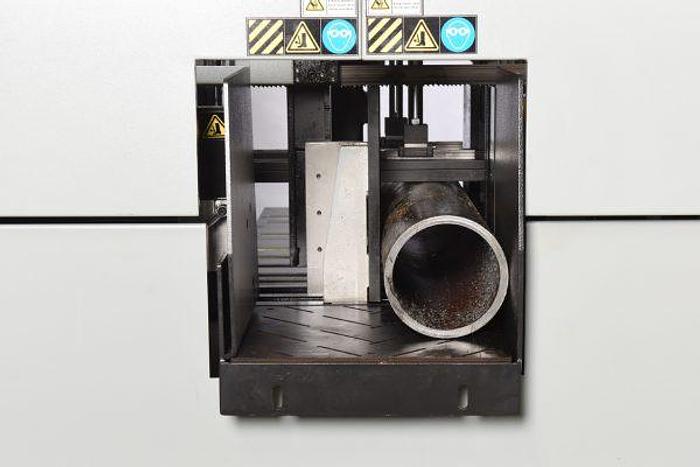

Automatic horizontal band saw providing accurate 90° metal cutting for medium to heavy-duty applications. Designed for safety with saw-in-a-box style.

A heavy duty shuttle vise powered by a ball screw and stepper motor provides material indexing up to 23” in a single stroke with multi-index capability. Its standard split front vise delivers a short material remnant length of 1.8″, reducing material waste. A steel guide arm is mechanically connected to front vise movable jaw provides proper guide arm to material spacing at all times.

Featuring a 14″ x 14″ capacity, 6 HP VFD motor, and 1 1/4″ blade, the H-360A is a reliable choice for your horizontal metal cutting applications.

STANDARD FEATURES

Heavy-duty cast iron saw head

Split front vise allows for short 1.8” remnant length

Fabricated shuttle features automatic multi-indexing up to 23” in a single stroke with automatic kerf compensation. Powered by ball screw and stepper motor

On-demand hydraulics save energy

Steel guide arms mounted on linear rails. Auto-adjustable guide arm for proper spacing

Variable vise pressure allows for cutting thin-walled material without deformation

6 HP VFD. True direct blade drive – no belts/pulleys

Full capacity, full stroking hydraulic vises

Hydraulic positive down feed

Blade chamber separates material from cut part

Cast iron band wheels

Automatic PLC, touch screen control programmable up to 100 jobs with 20 in queue

Replaceable blade brush

Robust steel base

Automatic chip removal auger

Blade breakage switch

Blade deviation monitor

Easy access electrical panel and hydraulics

Designed for safety with saw-in-a-box style

Out of stock switch

Mechanical band tensioning with digital readout

Replaceable carbide guide inserts

Safety door interlocks with RFID technology

Flood coolant with wash down hose

Laser light

LED Work light

OPTIONAL FEATURES

Full capacity hydraulic OH bundling

Mist lubrication

Power transformers

Vertical rollers

Reversible chip auger

Idler conveyors and accessories

Powered conveyors and accessories

Power transformer

Heavy-duty Shuttle Vise

A heavy duty shuttle vise powered by a ball screw and stepper motor provides material indexing up to 23” in a single stroke with multi-index capability. Its standard split front vise delivers a short material remnant length of 1.8″, reducing material waste.

Automatic Guide Arm

A steel guide arm, mounted on linear rails, is automatically adjustable for proper guide arm to material spacing at all times.

Dual Down Feed System

The H-320A’s electronic Dual down feed system allows the operator to control both feed rate and feed force, for more efficient cutting. Controlled by amperage draw chip load, the head feeding will automatically adjust based on relative chip load.

S-20 Horizontal Pivot Band Saw Angle Measurement

Touch Screen Control

The H-320A’s touch screen control is very intuitive and easy to program. The controller can be easily programmed, storing up to 100 different cutting jobs with 20 in queue and features several different cutting modes.

Specifications

| Manufacturer | Hydmech |

| Condition | New |

| Dimensions | 106” x 71” x 80” |

| Machine Weight | 4,400 lbs. |

| Blade Drive | 6 HP VFD |

| Blade Size | 1 1/4” x 14’ 9” |

| Capacity | 90° |

| Rectangular (HxW) | 14" x 14" |

| Round | 14" |

| Machine Voltage | 480 v (all other voltages require optional transformer) |

| Table Height | 34” |

| Automatic Multi-Indexing | 0-23″ |

| Remnant Length | 1.8″, 10″ with OH bundling |