Lux Series 3015

Lux Series 3015

or

Call 1-866-609-2672

Description

LUX Series fiber laser cutting machines offer exceptional power and quality of cut in a demanding and highly competitive market. . Our cutting head provides a safe and reliable workflow. , making burr-free cuts, ensuring a high quality finish.

LUX Series laser cutting equipment is designed to work safely Simple handling adapts perfectly to the production process that your company needs. .

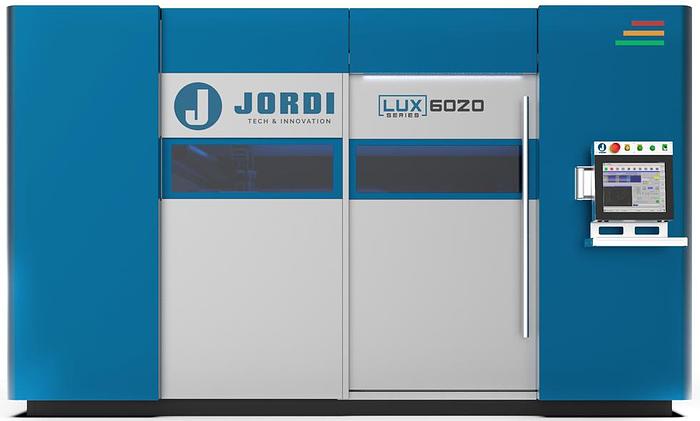

The LUX series equipment is a mix of constant innovation, experience and technology made by Jordi. Its strong points are:

Compactness

All LUX Series equipment is operator-friendly and very comfortable to handle. .

Durability

European manufacturing of the components means a long service life for all LUX series machinery .

Rigidity

Highly resistant construction assemblies due to the stability and robustness of the equipment's manufacture.

Security

For Jordi, safety is a non-negotiable priority. Jordi contributes to environmental protection, which we consider a key goal. .

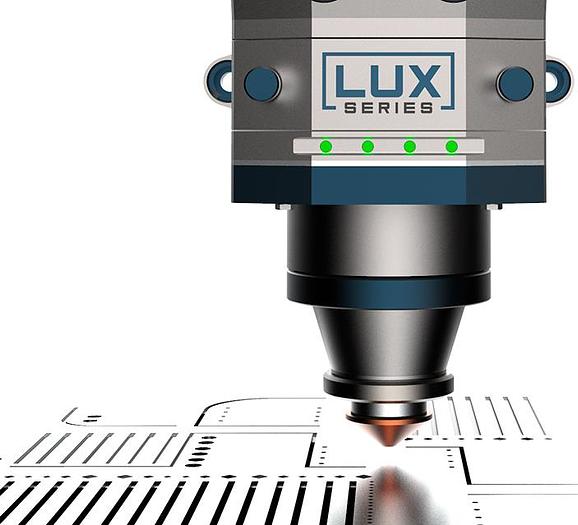

The gantry axis on the cutting deck (Y-axis) relies on a set of sliders and a high-precision guide for a linear drive. This guarantees high rigidity, minimal resistance to friction, and high load capacity. It is driven by a backlash-adjustable precision rack-pinion reduction rectifier system made from special hardened steel for maximum output and connected to an absolute metered servo motor.

The transverse linear axis (X-axis) features the same system as detailed above. A nozzle support head (Z-axis) equipped with a vertical guide system (spindle).

A constant distance is maintained between the nozzle and the material (only for metals) by means of a capacitive sensor. Before the cut, the non-contact cutting "head" detects the exact position of the sheet metal.

PRECITEC cutting head

This solid state laser cutting head features a high power PRECITEC Procutter with sensor for tracking metal surfaces and a glass-protected 200 mm focal lens holder.

The focal position adjustment is motorized and automatic.

• An anti-collision system is included.

EG 8030 adjustment box, 200 mm focal lens, protection glass, and nozzles for all thicknesses and ceramics are included.

The cutting head contains a 90° 100mm focal collimator.

Air tightness is improved compared to HPSSL and HPSSL + Compact design.

• Protection windows are motorized.

A LED bar shows pressure, temperature, contamination, and TCP.

Bluetooth® application allows for viewing parameters via mobile devices.

Loading and unloading system

Table systems and feeder exchangers are stopped when the operator enters the area protected by the infrared light barrier. Once out of the hazard zone, the user must reset the stop signal. .

For this reason, the relevant switch is only accessible to the operator outside the hazard zone. .

CAD/CAM Software and Control Panel

Lantek Expert CUT Plus CAD/CAM software is prepared to generate cut paths using the JORDI cut post processor (included in the software)..

Definition of cut geometries

Different fonts

Automatic generation of the cutting sequence

Continuous cutting that minimizes the number of perforations

• Cost calculation

Route optimization

Tables by thickness and materials

Workshop sheets

• Common cut with cut between pieces

Specifications

| Condition | New |

| Working Area | 3000 x 1500 mm |

| Speed X | 170 m/Min |

| Speed Y | 220 m/Min |

| Combined Speed | 280 m/Min |

| Acceleration | 2G |

| Repeatability | 0,02 mm |

| CNC | 670 mm |

| Max Lifiting Load | 2000 Kg |

| Resonator Power | From 2 Kw to 15 Kw |