RPC 1200 Mk3

RPC 1200 Mk3

Description

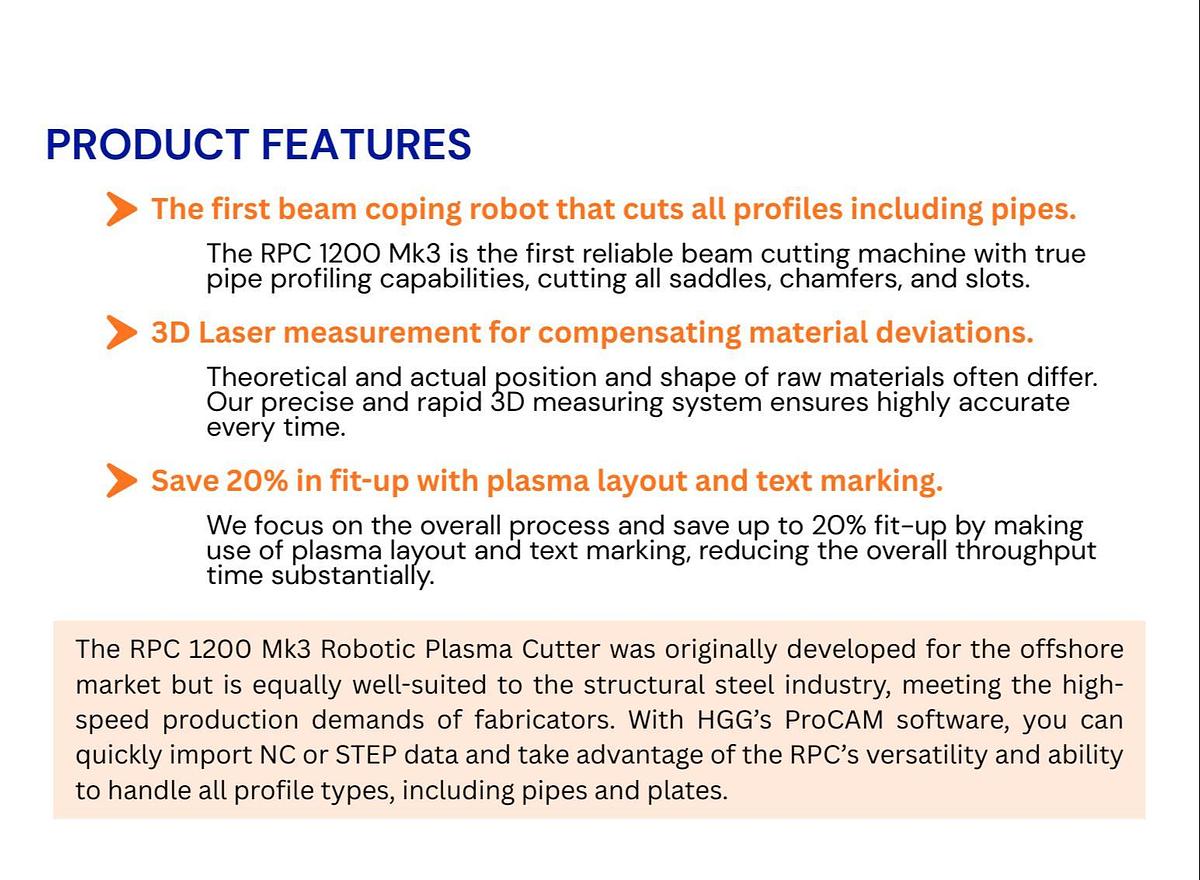

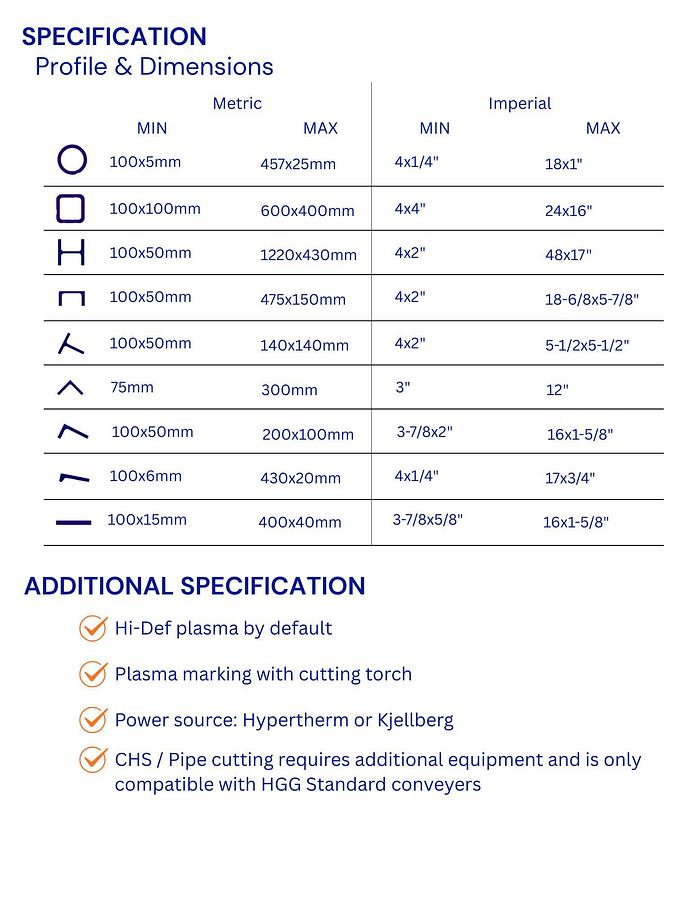

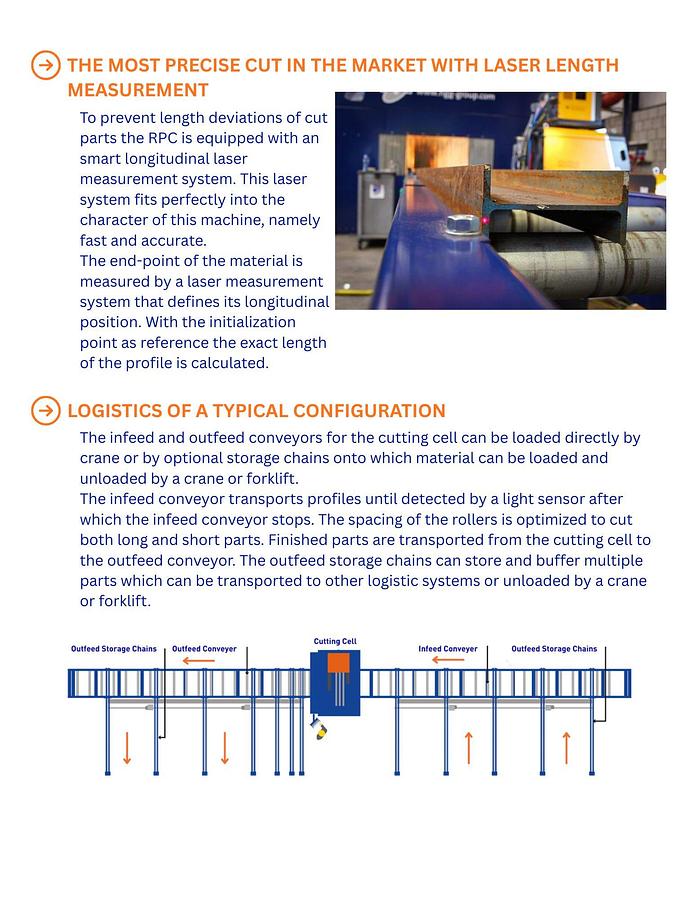

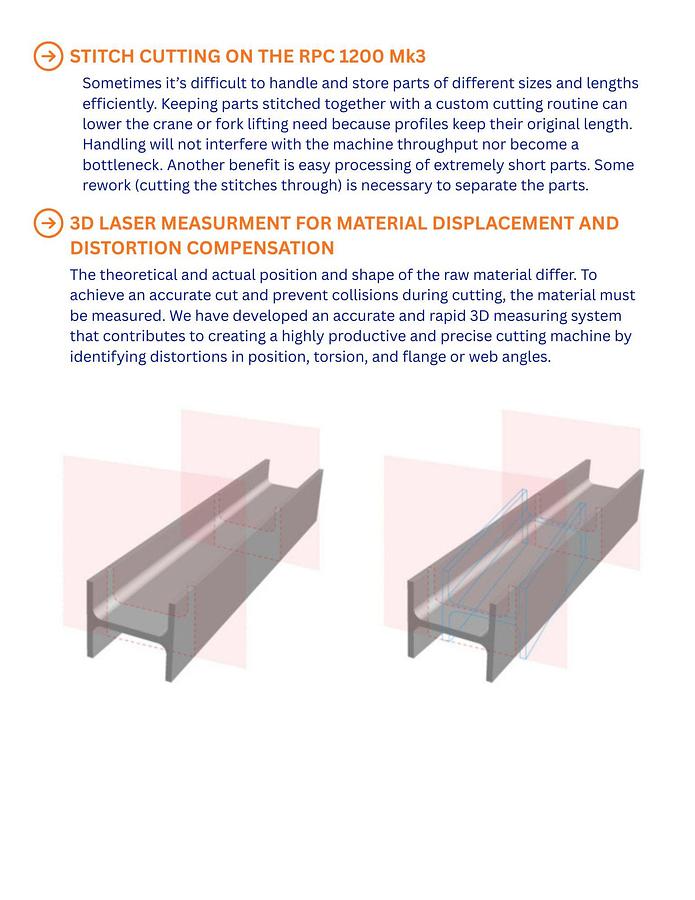

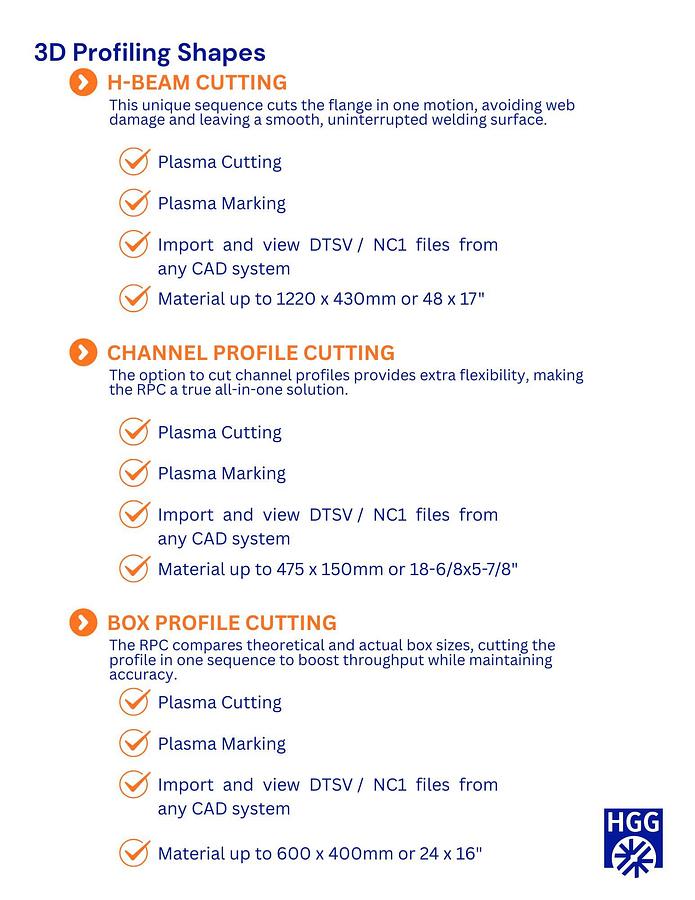

Industry: Offshore, Steel construction Process: Plasma The RPC 1200 Mk3 is the world’s first beam coping robot that also profiles pipes. This all-in-one solution, developed from our extensive experience with thermal 3D cutting, is the most versatile beam cutting solution available on the market. It offers high-speed plasma cutting of ready-to-fit parts, prepared for any desired connection, both welded and bolted. The RPC sets a new standard by offering an entire fabrication shop in a single machine. Product features The first beam coping robot that cuts all profiles including pipes. The RPC 1200 Mk3 is the first reliable beam cutting machine with true pipe profiling capabilities, cutting all saddles, chamfers, and slots. 3D Laser measurement for compensating material deviations. Theoretical and actual position and shape of raw materials often differ. Our precise and rapid 3D measuring system ensures a highly accurate cut every time. Save 20% in fit-up with plasma layout and text marking. We focus on the overall process and save up to 20% in fit-up by making use of plasma layout and text marking, reducing the overall throughput time substantially. The RPC 1200 Mk3 Robotic Plasma Cutter was originally developed for the offshore market but is equally well-suited to the structural steel industry, meeting the high-speed production demands of fabricators. With HGG’s ProCAM software, you can quickly import NC or STEP data and take advantage of the RPC’s versatility and ability to handle all profile types, including pipes and plates. Additional Specifications Hi-Def plasma by default Plasma marking with cutting torch Powersource: Hypertherm or Kjellberg CHS / Pipe cutting requires additional equipment and is only compatible with HGG Standard conveyers Precise Robot Positioning by Height and Transversal Axis for Optimal Performance A transversal axis and a height axis are responsible for the gross industrial robot positioning needed for cutting and marking 360 degrees around the material. The industrial robot will perform the fine movements necessary for accurate torch positioning and bevelling. The combination of the gross robot positioning and the use of a short industrial robot arm for fine positioning results in accurate cuts and rapid torch positioning. The most precise cut in the market with laser length measurement To prevent length deviations of cut parts the RPC is equipped with an smart longitudinal laser measurement system. This laser system fits perfectly into the character of this machine, namely fast and accurate. The end-point of the material is measured by a laser measurement system that defines its longitudinal position. With the initialization point as reference the exact length of the profile is calculated. Logistics of a typical configuration The infeed and outfeed conveyors for the cutting cell can be loaded directly by crane or by optional storage chains onto which material can be loaded and unloaded by a crane or forklift. The infeed conveyor transports profiles until detected by a light sensor after which the infeed conveyor stops. The spacing of the rollers is optimized to cut both long and short parts. Finished parts are transported from the cutting cell to the outfeed conveyor. The outfeed storage chains can store and buffer multiple parts which can be transported to other logistic systems or unloaded by a crane or forklift. Stitch Cutting on the RPC 1200 Mk3 Sometimes it’s difficult to handle and store parts of different sizes and lengths efficiently. Keeping parts stitched together with a custom cutting routine can lower the crane or fork lifting need because profiles keep their original length. Handling will not interfere with the machine throughput nor become a bottleneck. Another benefit is easy processing of extremely short parts. Some rework (cutting the stitches through) is necessary to separate the parts. 3D Laser Measurement for Material displacement and distortion compensation The theoretical and actual position and shape of the raw material differ. To achieve an accurate cut and prevent collisions during cutting, the material must be measured. We have developed an accurate and rapid 3D measuring system that contributes to creating a highly productive and precise cutting machine by identifying distortions in position, torsion, and flange or web angles. H-Beam Cutting This unique sequence cuts the flange in one motion, avoiding web damage and leaving a smooth, uninterrupted welding surface. Plasma Cutting Plasma Marking Import and view DSTV / NC1 files from any CAD-system Material up to 1220 x 430 mm or 48 x 17 “ Channel Profile Cutting The option to cut channel profiles provides extra flexibility, making the RPC a true all-in-one solution. Plasma Cutting Plasma Marking Import and view DSTV / NC1 files from any CAD-system Material up to 475 x 150 mm or 18-6/8 x 5-7/8 “ Box Profile Cutting The RPC compares theoretical and actual box sizes, cutting the profile in one sequence to boost throughput while maintaining accuracy. Plasma Cutting Plasma Marking Import and view DSTV / NC1 files from any CAD-system Material up to 600 x 400 mm or 24 x 16 “ Case Study Seamlessly connect to your existing CAD systems We partnered with several leading CAD/CAM companies to ensure seamless integration and the safe and easy transfer of data from your design to our machine. Integrate directly from TEKLA, SDS2, M-Suite, PypeServer, Foran, Stratus, STRUMIS, Ship Constructor, and many more. Efficient and Easy work preparation Design parts efficiently with HGG’s extensive library of predefined macro shapes. Visualize your creation before the first cut and catch any missing holes or shapes to ensure perfection. Utilize our advanced nesting algorithms to maximize material usage and dramatically reduce waste. Quick transition from CAD to cutting Simply upload your design from ProCAM to the machine, select the files you wish to cut, and verify them as needed. Push a button and watch the machine do the work. Experience the ease and efficiency of letting technology do the precision-cutting for you. Flawless assembly through precise layout marking Reduce human errors in measuring and positioning parts with accurate marking options, which facilitate quick and easy onsite assembly. Allow your machine to handle the marking of essential details such as part numbers, quality information, track and trace codes, or reference lines, simplifying the process of fitting parts together.

Specifications

| Manufacturer | HGG |

| Condition | New |

| Stock Number | 6618457 |