RoboRail

RoboRail

Description

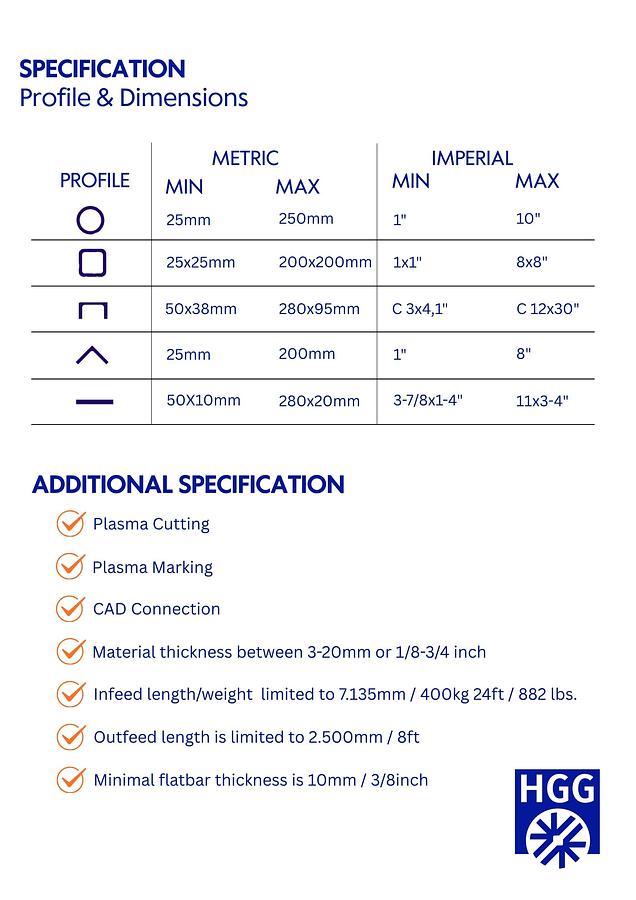

Industry: Steel construction Process: Plasma Many manufacturers think automation isn’t for them because everything they do is different. But that’s exactly why automation is essential! With the RoboRail, each unique part is cut and delivered 1-for-1, straight from your CAD files. Need complex cuts? Send it to the RoboRail. Require a diverse range of profiles? Send it to the RoboRail! This powerhouse will quickly become the backbone of your factory, freeing you up to focus on what your company does best. Embrace the future of manufacturing with our all-in-one plasma cutting machine: the RoboRail. Product features Maximize your shop efficiency. Maximize efficiency by letting the RoboRail handle your smaller, intricate metals. This allows your drill and saw lines to focus on what they do best. Includes layout marking options. Streamline your assembly process and minimize human error with advanced layout marking options. Compact footprint build for heavy duty work. The RoboRail's compact design transforms smaller shops into efficient, lean manufacturers.The all-new RoboRail will give you a more robust, reliable, and flexible solution you have always been looking for. HGG is the world leader in 3D profiling technology, and we have developed the new RoboRail in partnership with Automated Layout Technology, LLC to process a vast range of material quickly and accurately to length: cuts, copes, holes, layout marking, and more. Handrail pipe, stringer channels, box tubes, and angles are processed with a state-of-the-art Stäubli robot and reliable Hypertherm plasma system. Additional Specifications Plasma cutting Plasma marking CAD Connection Material thickness between 3 - 20 mm or 1/8 - 3/4 inch Infeed length/weight limited to 7.135 mm / 400 Kg 24 ft / 882 Lbs Outfeed length is limited to 2.500 mm / 8 ft Minimal flatbar thickness is 10 mm / 3/8 inch Cut profiles and hollow sections with one machine The RoboRail has the best of both worlds. A chuck for cutting the hollow sections by rotation. And a Staubli robot arm which gives the freedom to cut profiles without the need for rotation. One machine for copes, notching, cut-outs, holes, slot holes and markings. Streamline Production with CAD Integrations The RoboRail will let you work with DSTV and STEP-files directly from CAD-systems like SDS/2, Tekla Structures, SolidWorks, Inventor and many more. This will drastically reduce processing time and eliminates human error. With the RoboRail each and every piece can be different, and the machine will continue to process by reading files directly from your detailing. You can sit back and let the interface of the RoboRail guide you through the process. Automatic Infeed and Outfeed The RoboRail can be supplied with an infeed table which simplifies the material handling and guarantees a higher ‘burner on time’. Standard features include an outfeed table for short parts, which takes all the finished parts from the cutting cell and tilts them into a crate. Longer parts can be fed out onto a roller conveyor. Automated Pipe Cutting From handrail to medium sized truss structures, the RoboRail can do it all. In a matter of seconds. Plasma Cutting Plasma Marking Material 25 - 250 mm or 1 - 10 " Automated Angle Cutting The option to cut angle profiles gives you extra flexibility to complete any miscellaneous work. Plasma Cutting Plasma Marking Material 75 - 300 mm or 1 - 8 " Automated Channel Cutting The RoboRail is the best in processing stair stringers, platform reinforcement structures. Plasma Cutting Plasma Marking Material up to 280 x 95 mm or 12 x 3-1/8 “ Seamlessly connect to your existing CAD systems We partnered with several leading CAD/CAM companies to ensure seamless integration and the safe and easy transfer of data from your design to our machine. Integrate directly from TEKLA, SDS2, M-Suite, PypeServer, Foran, Stratus, STRUMIS, Ship Constructor, and many more. Efficient and Easy work preparation Design parts efficiently with HGG’s extensive library of predefined macro shapes. Visualize your creation before the first cut and catch any missing holes or shapes to ensure perfection. Utilize our advanced nesting algorithms to maximize material usage and dramatically reduce waste. Quick transition from CAD to cutting Simply upload your design from ProCAM to the machine, select the files you wish to cut, and verify them as needed. Push a button and watch the machine do the work. Experience the ease and efficiency of letting technology do the precision-cutting for you. Flawless assembly through precise layout marking Reduce human errors in measuring and positioning parts with accurate marking options, which facilitate quick and easy onsite assembly. Allow your machine to handle the marking of essential details such as part numbers, quality information, track and trace codes, or reference lines, simplifying the process of fitting parts together.

Specifications

| Manufacturer | HGG |

| Condition | New |

| Stock Number | 6618454 |