DO135/220-24M

DO135/220-24M

or

Call 1-866-609-2672

Description

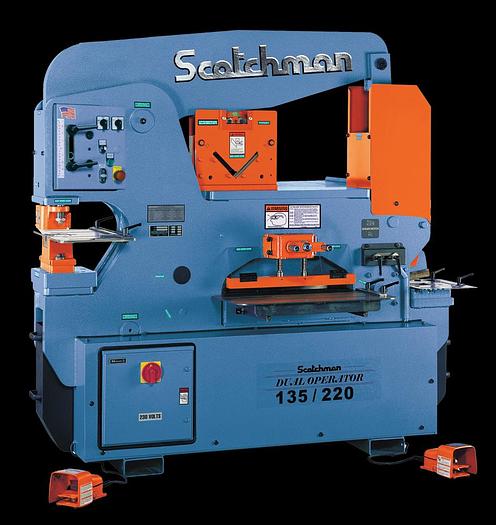

A dual-operator ironworker is often the best option when two simultaneous operations are required (e.g. punching and notching).

The dual operator 135-ton ironworker machine has a tandem hydraulic pump system designed to allow two operators to use the machine at the same time ensuring that both operations will have full hydraulic pressure and speed.

The DO135 has a 135-ton capacity punch and a 12" throat depth, which can punch a 1-11-16" hole in 1" thick mild steel. The DO 135/220-24M is made in America with many standard features that include: 6" x 6" x 1/2" angle shear and a rectangular notcher that can notch 3" x 5-3/4" through 1/2" material. The 24" flat bar shear features a low rake angle and can shear up to 1" x 12" and 1/2" x 24" steel plate. This machine also accepts optional equipment such as press brakes, rod shear, tube shear, picket tool, as well as custom-built tooling. The versatility of Scotchman ironworkers is unmatched as our machine's design allows for additional tooling to be quickly & easily swapped in and out of the tool table workstation so you can customize this machine to fit your needs!

This

American-made

ironworker is built tough and utilizes a hydraulic system with electric valves & remote foot pedals for ease of use, an adjustable electric stroke control with scale, and is backed by Scotchman’s industry leading 3-Year Warranty and lifetime customer support!

Dual Operator, 5 Stations

Dual operator allows for two operators to work at the same time at full capacity

135 Ton punch station

Keyed punch ram for safety

Punch gauging table with fence and scale

Die holder complete with 2" die insert

Punch nut with wrench & stripper

Adjustable swing-away stripper

LED work lights now standard equipment!

Jog control

Two adjustable electric stroke controls with scale

Two electric remote foot pedals

Tandem Hydraulic Pump

Two valves

Angle shear

Rectangle notcher with table, scale and guides

Flat bar shear with sabre blade

Shear table with miter fence

Tool table work area

Slug receptacles

Electrical box supplied with emergency palm button and lock-out tag-out accommodations

All guards necessary to comply with ANSI B11.5 safety standards

Forklift accommodations

Made in USA

Specifications

| Model | DO135/220-24M |

| Condition | New |

| Punching Capacity | 135 ton 1-11/16" in 1", 122 mt 42 in 25 mm |

| Special Tooling | 4" Max. Dia., 102 mm Max. Dia. |

| Throat Depth | 12", 305 mm |

| Flat Bar Shear(Sabre Blade - Standard) | 24" Length 1" x 12" 3/4" x 20" 1/2" x 24", 610 mm 25 x 305 mm 19 x 508 mm 12 x 610 mm |

| Angle Shear 90 degree | 6" x 6" x 1/2", 152 x 152 x 12 mm |

| Angle Shear 45 degreew/Toolw/Bar Shear | 3" x 3" x 3/8"4" x 4" x 1/2", 76 x 76 x 10 mm102 x 102 x 12 mm |

| Brake 12" | 90 ton, 81.6 mt |

| Brake 24" | 70 ton, 63.5 mt |

| Open End Brake | Max. 1/4" x 5"[Flat or Angle Iron], 6 x 127 mm |

| Pipe NotcherSchedule 40 | 3/4", 1", 1-1/4", 1-1/2", 2", |

| Rectangle Notcher | 3" x 5-3/4" x 1/2", 76 x 146 x 12 mm |

| 90 degree V-Notcher | 6" x 6" x 5/16"3" x 3" x 1/2", 152 x 152 x 8 mm76 x 76 x 12 mm |

| Notching in Leg of Channel | 6" to 10", 152 to 254 mm |

| Channel Shear | 2" to 6" adj., 51 to 152 mm adj. |

| Unistrut Shear | Samples Required, |

| Rod ShearRound (max.)Square (max.) | 9 Cavity - 1/4" to 1-1/4"1 Cavity - 1/4" to 1", 6 to 32 mm6 to 25 mm |

| Square Tube Shear | 1/2" to 2" 12 gauge, 12 to 51 mm0.105" / 2.7 mm |

| Picket Tool | 1/2", 3/4" & 1"16 gauge, 12, 19, 25 mm0.06" / 1.5 mm |

| Weld Coupon Bender (max.) | 2" wide x 3/8", 51 x 10 mm |

| Offset Die Holder | Max. 40 ton, Max. 36 mt |

| Strokes per minute in light material | 39 spm [Punch Station], 1/4" stroke |

| Strokes per minute in heavy material | 15 spm [Punch Station], 3/4" stroke |

| Hydraulics | 3,500/3,500 psi, 241/241 bar |

| Motor Standard | 10 hp208/230/460, 380/575v; 3 ph, 7.46 kW |

| Motor Optional | 10 hp 220v, 1 ph, 7.46 kW |

| Dimensions | L: 83"W: 38-1/2"H: 76-1/2", L: 211 cmW: 98 cmH: 194.5 cm |

| Shipping Weight (may vary) | 6,204 lbs., 2,814 kg |

| One round punch & die | max. diameter 1-1/4" |

| Warranty | Three years on parts |